Polyester/cotton Braided Sleeve has the characteristics of high conductivity and strong performance, and is suitable for non-horizontal energizing movements and medium and low voltage circuit breakers.

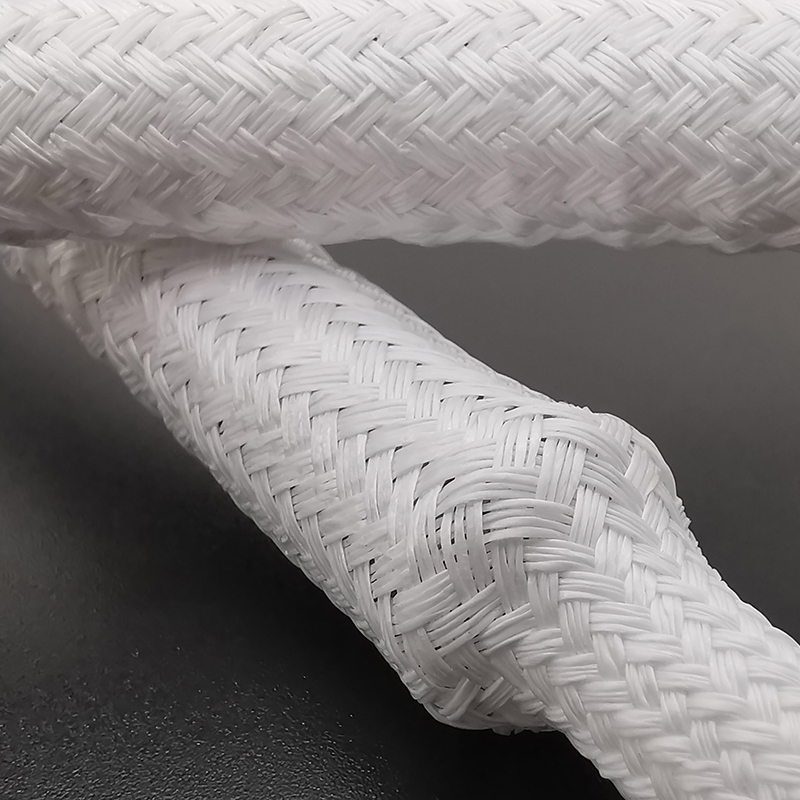

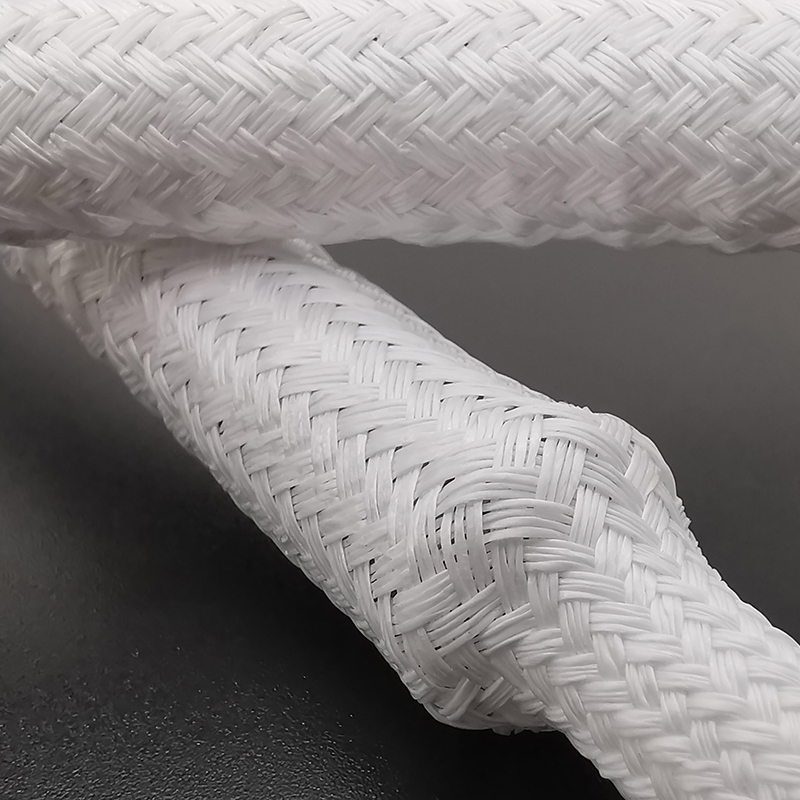

The DC resistance (20°C) of Polyester/cotton Braided Sleeve shall not exceed 0.022Ωmm2/m, and the DC resistance (20°C) of tin Polyester/cotton Braided Sleeve shall not exceed 0.0234Ω.mm2/m. Copper core wire soft connections are used in high and low voltage electrical, vacuum pump household appliances, mining explosion-proof switches and vehicles, electric locomotives and related products for soft connections. The Polyester/cotton Braided Sleeve is braided with bare copper core wire or tinned copper wire, and is made by cold extrusion. It can be electroplated with tin or silver according to customer specifications. Suitable for non-horizontal energized movements and medium and low voltage circuit breakers.

Polyester/cotton Braided Sleeve is used as the conductor, and air-conditioning copper pipes are used on both sides. The surface of the air-conditioning copper pipe is gold-plated. The size of the connector is manufactured according to the customer's supporting facilities specifications, and then according to the processing, it is made into a soft connection, soft grounding device, and conductive With high efficiency and strong capabilities, it can be manufactured according to user requirements.

Competition in the market for mid- to low-end cable and wire products is fierce, and product quotations will show a downward trend. Compared with special cable manufacturing companies, the gross profit margin is higher, and the industry prospects are promising. In order to better and more effectively protect metal cables, many manufacturing suppliers consider using insulating tubes for safety protection.

For example, upgrading polyester Polyester/cotton Braided Sleeve, protective sleeves, PET high flame retardant Polyester/cotton Braided Sleeve, etc., to make them more competitive and more integrated into the environment. At the same time, it also saves a lot of energy. Maintenance costs are reduced and the service life of metal cables is extended.

As a new type of waterproof casing, Polyester/cotton Braided Sleeve is mainly made of high-voltage polyethylene PE and seamless steel pipe. It is a commonly used insulating tube for protecting wires and cables because it has better insulation. Performance, reliability and these characteristics make it widely used in wire harness, mechanical equipment, electronic wire harness and other industries.

In terms of the characteristics of this product, it is mainly reflected in the following aspects: First, this product has a relatively obvious conductivity, and is relatively single-specific, that is, it can only be injected through the positive stage and discharged through the negative stage. Secondly, the product has a close relationship with semiconductor devices from beginning to end. This is also an early product among semiconductor material products.

As far as this field is concerned, after more than ten years of continuous development, the market operation scale has gradually emerged. The technical strength has also been greatly improved compared to the past, which all needs to benefit from the continuous technological innovation within the field.