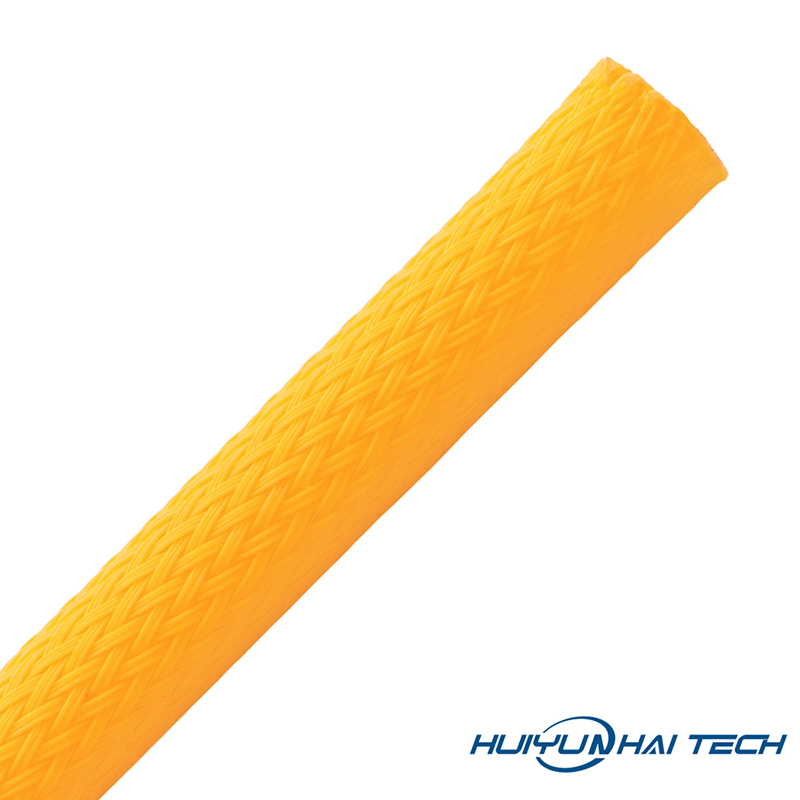

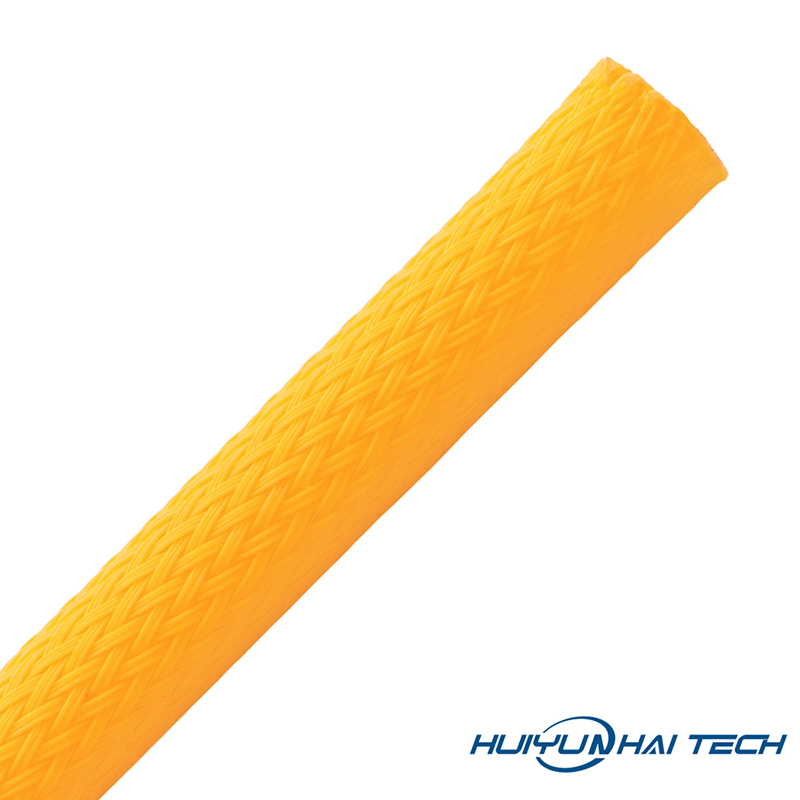

Polyester/Cotton Braided Sleeve is made of environmentally friendly PET and other materials. It has good wear resistance, expandability, smoothness, flame retardancy and breathability and heat dissipation performance. The product is commonly used in computer power cords and speakers. For the maintenance and decoration functions of video lines, lighting, refrigerators, washing machines and other electrical products as well as optical cables, motorcycles, vehicles, airports and other routes, brushed or three-wire braids with different widths can be used according to user requirements. Polyester/cotton Braided Sleeve in different colors and patterns.

1. Common causes of defects in general Polyester/

Cotton Braided Sleeve ①The first is the problem of the material itself. If PET filament is produced from particles, it is generally not heat-resistant, and the woven equipment is uneven and has no gloss.

② During the production process, the yarn was not paid attention to, resulting in one or two yarns in the middle not being aligned neatly, and yarn skipping would occur during knitting.

2. The key factors for the quality of braided tube and cable accessories are diverse. Generally, there are the following aspects:

① Electrical performance, the quality of electrical performance is the main criterion for evaluating the quality of cable accessories. It mainly considers whether the electromagnetic field distribution of cable accessories is effective, whether the method to improve the electrostatic field distribution is appropriate, the electrical strength of the raw material, Dielectric loss and insulation margin of the product, etc. At the same time, the stability of the electrical properties must also be considered, including the chemical, physical properties and structural stability of the cable accessories materials, such as ground stress controlling material properties. Whether it is stable, whether the ground stress cone is easy to deform, the harm of cable insulation shrinkage to the electromagnetic field distribution of cable accessories and how to avoid it, the compatibility of various material fusions, the stability of the fusion page performance, etc. In addition, it should also be Consider the thermal properties of cable accessories, such as dielectric loss, loop resistance and stability of conductor connections, heat transmission and release, and the interference of thermal expansion and contraction on the electrical properties of various components and the performance of mechanical equipment, etc.

②Sealing performance and water-proofing performance directly affect the performance and service life of electrical equipment of cable accessories. Is the sealing structure of the terminal equipment reliable and stable? Generally speaking, the intermediate joint should also have a metal material that matches it. Water-resistant enclosures, especially if directly buried or used in humid environments.

③ Mechanical performance, terminal equipment should have sufficient bending strength and earthquake resistance, and intermediate joints should be able to withstand some tensile strength and measures to avoid damage from external forces.

④Processing process performance. Processing process performance is an important criterion for the design and model selection of cable accessories. The installation process should be as simple as possible, which is conducive to on-site construction, has a short construction period, and does not have high requirements on the site environment and the technical strength of employees, the assembly quality is very easy to control, the quality is reliable, etc.